news

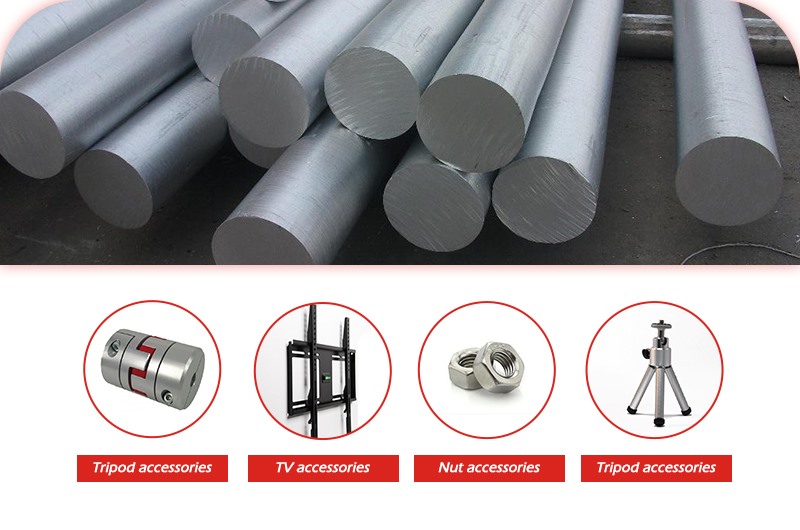

6262 aluminum rod bar

General 6062 characteristics and uses: Good machinability and high strength; high corrosion resistance and applied coating acceptance. Finishing characteristics better than 2011, 2017, 2024, 7075 and equal to 6061. The T9 temper offers excellent residual stress control.

|

Chemical Composition Limits |

|||||||||||||

|

Weight% |

Al |

Si |

Fe |

Cu |

Mn |

Cr |

Ti |

Mg |

Zn |

Bi |

Pb |

Other Each |

Others Total |

|

Alloy 6262 |

Bal |

0.40 / 0.80 |

0.70 max |

0.15 / 0.40 |

0.15 max |

0.04/0.14 |

0.15 max |

0.80/1.20 |

0.25 max |

0.40-0.70 |

0.40-0.70 |

0.05 max |

0.15 max |

|

Material |

Temper |

Diameter (") |

Tensile Strength ksi (min) |

Yield Strength ksi (min) |

Elongation in 2" |

|

Alloy 6262 Bar |

T6/T651 |

<8 |

42 |

35 |

10 |

|

Alloy 6262 Bar |

T9 |

0.125-2.00 |

52 |

48 |

5 |

|

Alloy 6262 Bar |

T9 |

2.00-3.00 |

50 |

46 |

5 |

Uses: Camera parts, couplings, marine fittings, decorative and misc. hardware, hinge pins, knobs, magneto parts, nuts, oil line fittings, appliance fittings, roller skate parts, steam iron parts, TV fittings, tripod fittings, valves and valve parts.