news

6082 aluminum extrusion

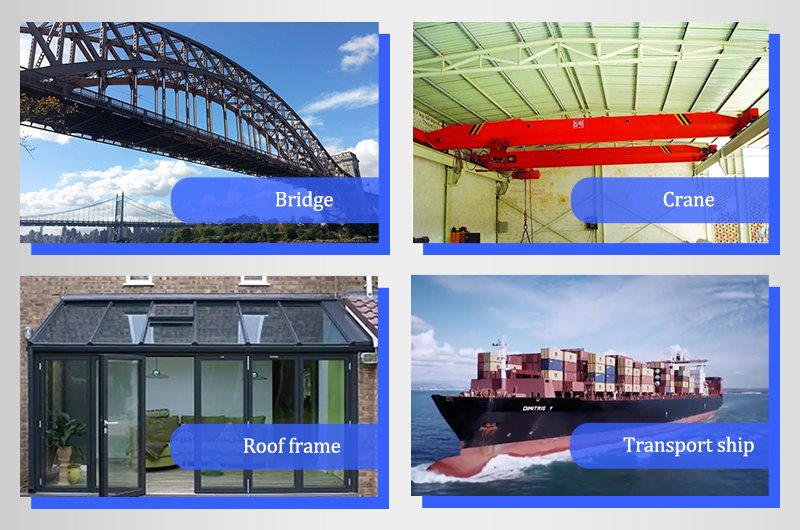

6082 aluminum extrusion belongs to Al-Mg-Si series heat-treatable-strengthened aluminum alloy with moderate strength, good weldability and corrosion resistance, and is mainly used in transportation and structural engineering, such as bridges, cranes, roof structures, traffic Vehicles and transport ships, etc.

Since the biggest feature of 6082 aluminum extrusion is that it contains refractory metal Mn, the presence of an appropriate amount of Mn can easily lead to intragranular segregation and reduction of plasticity in the solid-liquid region, resulting in insufficient crack resistance. Therefore, three main points should be paid attention to in the melting and casting process: first, the melting process should be Pay attention to control the temperature between 740 and 760 ℃ and stir evenly to ensure that the metal is completely melted, the temperature is accurate, and the composition is uniform. Second, the casting should consider that metal Mn increases the viscosity of the alloy and reduces its fluidity, which affects the casting properties of the alloy. The casting speed should be appropriately reduced and controlled within the range of 80-100mm/min. Third, increase the cooling intensity and speed up the cooling rate to help eliminate the phenomenon of intragranular segregation. Control the intensity of primary cooling and increase the intensity of secondary cooling to reduce the stress concentration during casting and avoid ingot crack defects. The cooling water pressure should be controlled within the range of 0.1 ~ 0.3MPa.

6082 aluminum extrusion has large deformation resistance and high mechanical properties. Through the homogenization process, the alloy structure is improved, and three main effects are achieved: fully solid-dissolving Mg2Si phase; eliminating intragranular segregation; β (Al9Fe2Si2) phase transformation to α (Al12Fe3Si2) phase, and refining iron-containing phase particles. Since the presence of Mn in the alloy can reduce the transformation temperature and shorten the transformation time, and in order to maintain the extrusion performance and extrusion effect of the alloy, a medium temperature homogenization process is adopted, that is, the homogenization temperature is 555 ~ 565 ℃;

6h; cooling rate ≥200℃/h.