news

6063 Aluminum Tube for Finned Tube

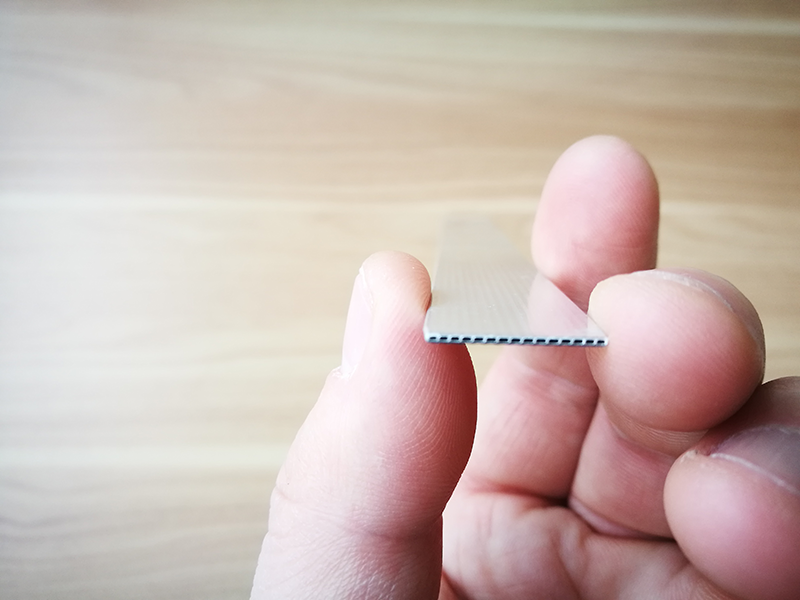

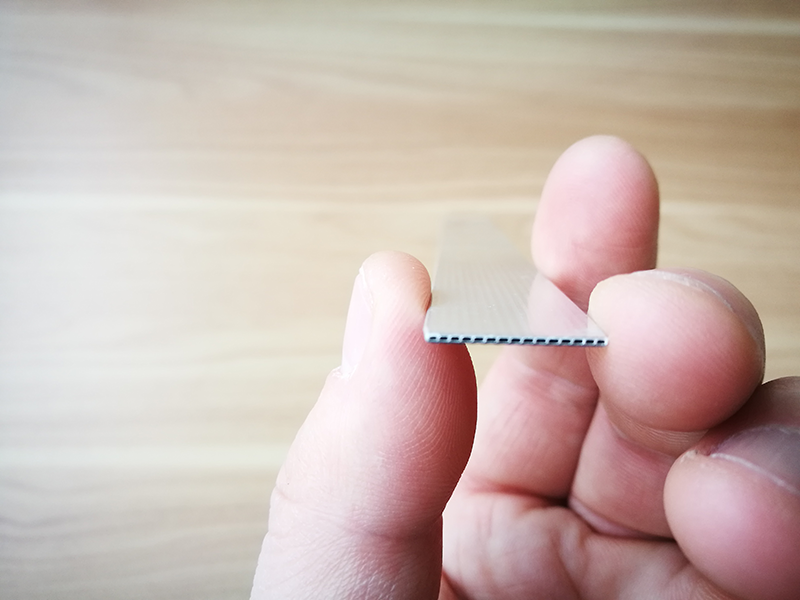

Large-scale radiators in the air-cooled heat exchange industry use steel-aluminum composite tubes as heat-dissipating base tubes, which are finned tubes (Fig. 1) rolled by high-speed rolling mills that are sleeved on steel tubes with excellent heat-dissipation effect. 1060 aluminum tube has the advantages of low strength, good plasticity, easy rolling, and high rolling fin height, which can maximize the heat dissipation area and achieve a very good heat dissipation effect. It is widely used at present, but its surface hardness is low. The fins are easy to fall, etc. High-end high-hardness aluminum alloy rolled finned tubes in the international market are rolled with 6063 aluminum alloy tubes. Compared with 1060 pure aluminum tube rolled aluminum alloy finned tubes, 6063 Aluminum Tube for Finned Tube manufactures high-hardness aluminum alloys. The rolled finned tube is more resistant to rewinding, easy to clean, not easy to scale, has better heat exchange performance, and has a service life 1/3 longer than that of 1060 pure aluminum finned tube.

According to the market demand, through chemical composition adjustment, a reasonable extrusion process is formulated, and the final 6063 Aluminum Tube for Finned Tube produced fully meets customer requirements. The fin height is ≥15mm and the surface is smooth, which meets the technical indicators of imported similar products and completely replaces The imported similar products have been used for large international air-cooled heat exchange enterprises.

(1) The main strengthening phase elements of 6063 aluminum alloy are Mg and Si, the content of which has a great influence on the strength of the material, especially when there is excess Si, the strength of the material is very high, and its elongation will increase with Mg, Si. The increase of Si content has a downward trend. Strict control of alloy elements such as Zn, Cr, and Mn is helpful to the elongation of the material; the Fe content is controlled at 0. 13% ~ 0.16%, adding Ti element will refine the grain of the material to achieve the purpose of improving plasticity. By comparison with Alloy C, the chemical composition Fe:

- 13% to 16%, Si: 0. 22% to 0. 26%, Mg: 0. 50%~

54%, Ti: 0. 02% to 0. 04%, the rest are less than 0. 02%;

(2) The extrusion process has a great influence on the mechanical properties of the material and the quality of the rolled fins. The extrusion temperature has a great influence on the strength and plasticity of the material, and the welding quality is not good at low temperature, so high temperature extrusion at 460°C ~ 480°C should be used; products produced without fan have good elongation, and the maximum The degree of reduction of natural aging can make the material maintain stable performance (especially elongation) for a long time, and improve the rolling performance of rolled finned tubes. According to the above process system, the fin height ≥

15mm, smooth surfaced 6063 Aluminum Tube for Finned Tube.